All Facilities | All Instruments

Nanofabrication Facility

Instruments and Tools

Deposition

-

Atomic Layer Deposition (ALD) System ›

The Ultratech Fiji G2 system is a load-locked ALD system capable of both thermal and plasma-enhanced depositions of various dielectric and metallic films

-

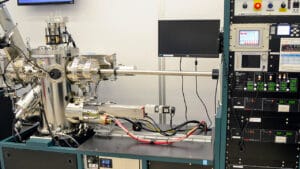

DC/RF Sputter Deposition System ›

The AJA Orion Sputtering System is a load-locked sputtering system capable of depositing metal and dielectric films over a substrate up to 6 inches in diameter.

-

E-beam & Thermal Evaporation System ›

The AJA Orion 8E Evaporator System is capable of both electron beam (e-beam) and thermal evaporation.

-

Organics/Oxides E-beam Evaporator ›

The AJA Organic evaporator is a combination ebeam and thermal evaporator. The ebeam evaporator in the tool is primarily used to evaporate oxides and magnetic materials. The thermal evaporators are used to evaporate low melting point materials, such as organic semiconductors.

-

Plasma Enhanced Chemical Vapor Deposition System (PECVD) ›

The Oxford PlasmaPro System 100 PECVD is load-locked tool, capable of depositing silicon oxide, silicon nitride, amorphous silicon, and other films.

-

Sputter Coater ›

Sputter coating uses ionized argon to vaporize gold atoms from a target and deposit them in a thin layer onto a sample.