Posted on April 20, 2021 in ASRC News, Featured News, Nanoscience Initiative

New research from the lab of Adam Braunschweig, a faculty member in the Nanoscience Initiative at the Advanced Science Research Center at The Graduate Center, CUNY (CUNY ASRC) and a professor of chemistry at Hunter College and The Graduate Center, marks a milestone in the field of nanotechnology. The work is poised to accelerate research on polymer films by furthering scientists’ understanding of polymer growth and properties.

The new approach will facilitate studies of “fundamental and technological problems where films and coatings play a major role,” Braunschweig said. “This includes optical coatings, antifouling coatings, scaffolds for tissue culture, and sensors.” Beyond benefiting research scientists, the discovery could advance areas of industry, the arts, and government.

The researchers developed a photochemical printing method that lets them test how different polymers grow under hundreds of different conditions, much more quickly and easily than before. It also allows for highly complex “6D printing” of polymer brush patterns — surfaces made by building polymer chains upward from a substrate base. The method gives researchers control over the x- and y-position of each polymer “pixel,” the polymers’ height, their chemical structure, and the way they react to light and heat.

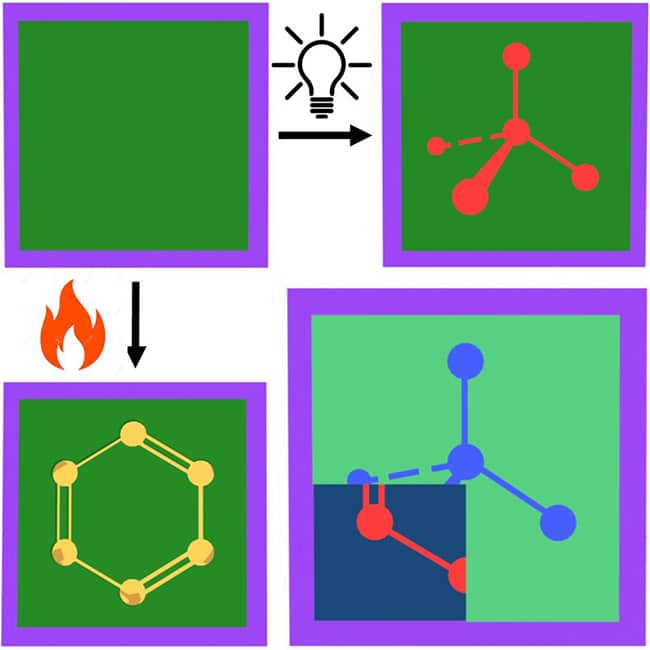

In a new paper published in Advanced Materials, Braunschweig and colleagues demonstrate this technique by printing patterns of unprecedented complexity with multiple polymer types. They were able to print each polymer to the same height, and hide two different images in the printed surface: one that shows up when heated, and another revealed under UV light.

Previously, a main challenge was the difficulty of testing how factors like light intensity, monomer concentration, and photocatalyst concentration affected each type of polymer. With the new method, researchers were able to test over 400 different conditions and select the right ones that would let them print each polymer to the same height.

“With our printing technique we can test hundreds of different formulations at a time, whereas conventionally, each experiment would test only a single formulation,” Braunschweig said. This reduced cost of experimenting could give polymer films research a huge push forward.

In the new study, the researchers printed a surface made partly of a polymer that collapses at a certain temperature. When heated, part of the printed surface crumples, revealing a hidden image. By printing a layer of fluorescent monomers on the top of the surface, they incorporated a second image that shows up under UV light.

“I think my students have a lot of fun choosing the images when they get a printing method working,” Braunschweig said. “Yerzhan Zholdassov, the lead author, had complete freedom to choose the images for the 6D pattern, and I thought the choice of a tetrahedral carbon and a benzene ring were clever as they represent some very simple molecules, whereas the patterns are the result of some of the most complex chemistry yet developed.”

Summing up the potential impact of the discovery, Braunschweig said, “Really, this is a printing technology, so the applications are limited only by the imagination of the user.”