All Facilities | All Instruments

Radio Frequency and Millimeter Wave Facility

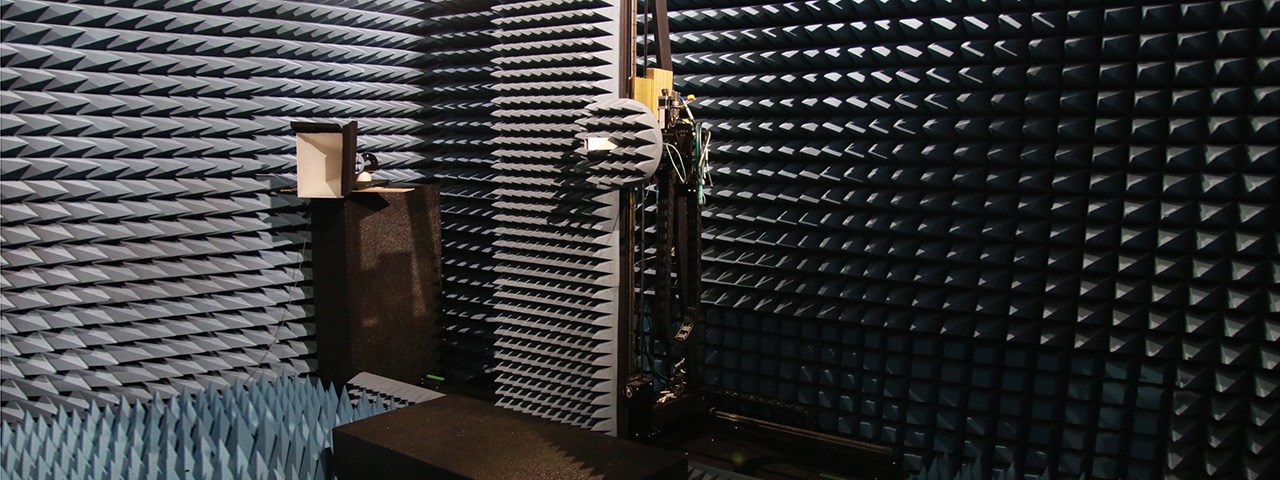

The Radio Frequency and Millimeter-wave (RF/mm-wave) Facility includes electronics fabrication and measurement units.

- The electronics fabrication unit offers a complete in-house PCB prototyping (multilayer rigid and flex) through high-end laser and mechanical equipment. Furthermore, the fabrication unit provides a complete component placement and rework cycle including high-end fully- and semi-automatic rework stations enabling desoldering, soldering, and residual solder removal of SMDs and BGAs as small as 01005.

- The measurement unit offers an anechoic test chamber capable of measuring electromagnetic radiation, high-end spherical nearfield measurement system, planar nearfield scanner (all in frequencies ranging from 1-110 GHz), and high-end PNAs and other required equipment for a fully in-house measurement cycle.

Complete the online application to become a user of this and other ASRC facilities.

Facility Details

Electronic Fabrication Equipment

- 3D printer: Raise3D Pro2 Plus

- Laser prototyping machine: ProtoLaser U4

- Mechanical prototyping machine: ProtoMat S104

- Plating machine: Contac S4

- Pick and place machine: Finetech Core Plus

- Reflow oven: ProtoFlow S N2

- Multilayer press: Multipress S

- Soldering machine: Weller WXD2

Measurement Equipment

- Microwave Network Analyzer: N5247B PNA-X

- Arbitrary waveform generator: M8195A

- Real-Time Oscilloscope: MXR and UXR Series

- Anechoic chamber

- Different sources

- Robotic system

Rates are charged by the hour.

| CUNY Rate | Academic Rate | Start-up Company Rate | Industrial Company Rate | |

| Anechoic chamber | $75 | $100 | $500 | $500 |

| Weller WXD2 | $31 | $50 | $31 | $31 |

| ProtoLaser U4 | $102 | $120 | $400 | $400 |

| ProtoMat S104 | $102 | $120 | $230 | $230 |

| MultiPress S | $77 | $108 | $170 | $170 |

| Contac S4 | $77 | $104 | $160 | $160 |

| FineTech Core+ | $77 | $110 | $157 | $157 |

| Raise3D Pro2 Plus | $5 | $6 | $15 | $15 |

| PNA | $20 | $176.40 | $176.40 | $176.40 |

| Waveform generator | $20 | $43.65 | $43.65 | $43.65 |

| Infiniium oscilloscope | $20 | $43.65 | $43.65 | $43.65 |

| ProtoFlow S N2 | $10 | $59.51 | $93.43 | $93.43 |

| Robotic system | $20 | $29 | $45 | $45 |

| Director’s time | $70 | $70 | $70 | $70 |

For more information, please contact:

-

Arno Thielens

- Research Associate Professor, Photonics Initiative

- Director, Radio Frequency and Millimeter Wave Facility